We’re proud to have welcomed AeroTruss to the Spencer Group family in 2025. Specialising in high-quality aluminium truss systems, AeroTruss provides modular structures that combine strength, flexibility, and reliability for a wide range of applications.

AeroTruss is a modular, moving access system purpose-built for bridge and structure maintenance, engineered to be quickly deployable, robust and versatile, even under the most demanding working conditions.

Built from high-strength structural aluminium, AeroTruss provides a secure working platform that can adapt to almost any bridge geometry, whether long spans, curved decks or complex under-deck profiles.

The system is made from a range of pre-made modular components, which can be assembled into a bespoke configuration to suit the specific bridge.

This flexibility makes it ideal for inspections, repairs, painting, grit-blasting or other maintenance tasks where traditional scaffolding or fixed access might be impractical, and which might otherwise need weekly inspections, whereas AeroTruss only needs inspecting every six months.

One of the standout features is the fully integrated retractable encapsulation system, bolted at nodal connections to ensure structural rigidity and environmental containment.

This offers enhanced safety and control, particularly important when dealing with debris or contaminants during works such as grit-blasting or repainting.

In terms of technical capability, AeroTruss supports spans up to 50 m, with a working platform capacity of 400 kg/m² for personnel and 25 kg/m² for grit payload, providing the strength needed for heavy-duty bridge maintenance operations.

AeroTruss provides the strength and load-bearing capacity needed for heavy-duty maintenance operations on bridges, enabling teams to work efficiently and safely, even in challenging conditions.

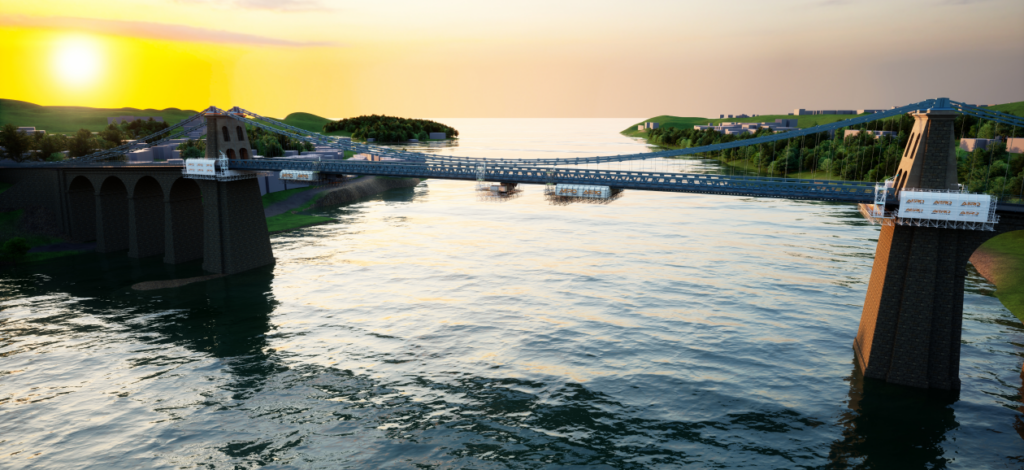

The system is planned to be installed on the Menai Suspension Bridge in 2026, as part of Phase 2 of the ongoing maintenance works being carried out by Spencer Bridge Engineering. The system will enable safe, efficient under-deck access for tasks including painting and structural repairs, supporting the preservation of this historic structure in preparation for its bicentenary in 2026.

We believe AeroTruss represents a significant evolution in how we approach the care and upkeep of bridges and heritage structures. By combining adaptability, safety, and ease of deployment, it allows us to conduct maintenance with minimal disruption, improved quality and greater protection for the structures we serve.